Staying Ahead: How Continuous Tech Training Fuels Innovation

Key Takeaways:

- Upskilling your workforce empowers them to identify areas for improvement and develop solutions, driving a culture of innovation.

- Strategic planning, resource allocation, and adaptable content address common hurdles to ensure training delivers a strong return on investment.

- Integrate foundational technical concepts and focus on transferable skills to equip your workforce for emerging technologies.

- Utilize online modules, simulations, and collaborative platforms to create engaging and accessible training experiences.

- Leaders who actively participate in and advocate for continuous learning set the standard and foster a thriving learning environment.

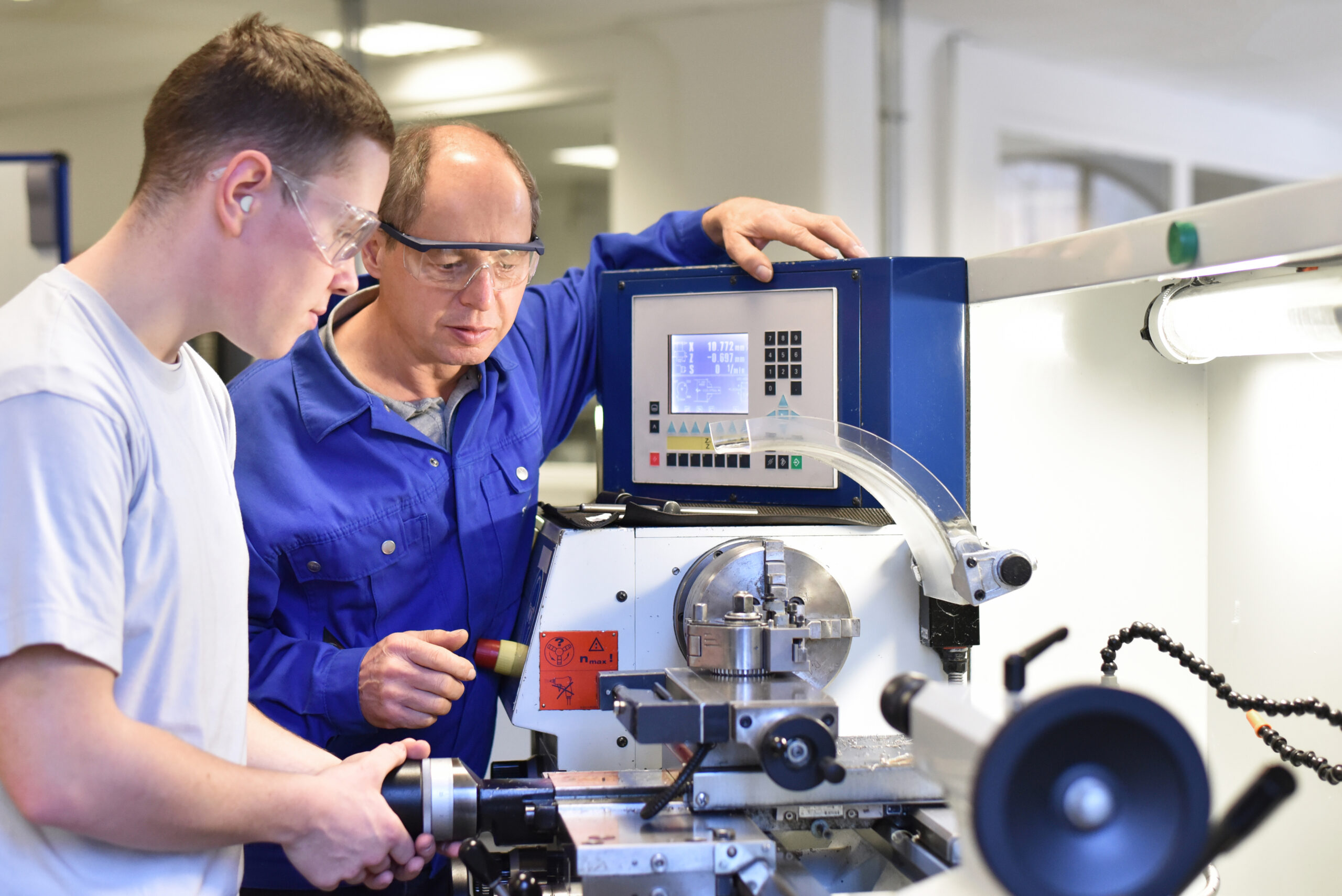

The industrial landscape is in a constant state of flux. New technologies are rapidly reshaping the workplace, demanding a skilled workforce that can adapt and evolve. For businesses across all sectors, prioritizing continuous technical training for their employees has become a critical strategy for staying competitive and driving innovation.

This article will explore the essential role that ongoing learning plays in equipping employees with the latest tools and knowledge. We’ll examine why staying abreast of the newest advancements is no longer optional, but a core requirement for fostering a culture of innovation and achieving long-term success.

The Importance of Technical Training for Industrial Innovation

In the context of industrial innovation, continuous technical training is paramount. Companies recognizing this, such as Orion Technical Solutions among others, emphasize the necessity of updating technical skills to keep pace with rapidly advancing industrial technologies. This ongoing learning environment directly fuels innovation in several key ways.

A technically proficient workforce is better equipped to identify areas for improvement within existing processes. By understanding the intricacies of their equipment and software, employees can recognize inefficiencies and potential bottlenecks. This awareness paves the way for creative problem-solving and the development of innovative solutions that optimize production and streamline operations.

For instance, consider the rise of automation in manufacturing. Employees with a strong foundation in robotics and automation principles can actively participate in designing and implementing these systems. Their technical expertise allows them to not only operate the new technology but also to identify opportunities to integrate automation seamlessly into existing workflows, ultimately enhancing overall efficiency.

Barriers to Effective Technical Training

While the benefits of continuous technical training are undeniable, implementing effective programs can present challenges for businesses. Here, we’ll explore some common hurdles and practical solutions to ensure your training initiatives deliver a strong return on investment.

Resource Allocation

Securing adequate funding and personnel to develop and deliver training programs can be a hurdle. Budgetary constraints may limit access to high-quality training materials or external expertise. Additionally, dedicating internal staff time to training development can strain existing workloads.

Explore cost-effective training solutions, such as online learning modules or industry partnerships. Look for opportunities to leverage existing employee expertise by encouraging knowledge-sharing sessions or peer-to-peer mentoring programs.

Scheduling and Time Management

Employees often juggle busy workloads, making it difficult to carve out dedicated time for training. Inflexible scheduling can create participation barriers, leading to low engagement and incomplete training cycles.

Consider offering bite-sized, micro-learning modules that can be completed in short bursts during downtime or shift changes. Explore flexible learning options, such as asynchronous online training or blended learning models that combine online modules with instructor-led sessions.

Content Relevance and Engagement

Training programs that are generic and one-size-fits-all usually don’t engage employees or target their specific skill gaps. When the content is disconnected and doesn’t relate to real-world situations, it often results in low retention rates and has little impact on everyday work.

Conduct needs assessments to identify the specific technical skills required by different teams or departments. Develop targeted training programs that directly address these needs and incorporate practical scenarios relevant to employees’ daily tasks. Encourage interactive learning experiences through hands-on activities, simulations, or case studies to boost engagement and knowledge retention.

Adapting Training to Technological Advances

The rapid pace of technological change presents a unique challenge for technical training programs. Curriculums that remain static risk becoming outdated quickly, leaving employees with skill sets that don’t align with the demands of the evolving industrial landscape. To maintain a competitive edge and foster a culture of continuous innovation, training programs must embrace agility and responsiveness.

Here are some key strategies for ensuring your training programs keep pace with technological advancements:

- Future-Proofing Curriculums: Integrate foundational technical concepts that apply across a range of technologies. For instance, a strong understanding of data analysis principles can be valuable regardless of whether employees are working with traditional manufacturing equipment or implementing new sensor-based monitoring systems.

- Focus on Transferable Skills: In addition to technical expertise, prioritize the development of transferable skills like critical thinking, problem-solving, and adaptability. These skills empower employees to learn new technologies independently and navigate unforeseen technological shifts.

- Embrace Microlearning and On-Demand Training: Shorter, focused training modules allow employees to quickly acquire new skills relevant to emerging technologies. Additionally, on-demand training resources provide flexibility for learning at the point of need, ensuring employees have the knowledge they need when they need it.

- Leverage Industry Resources and Partnerships: Many industry associations and technology vendors offer comprehensive training programs and certifications focused on cutting-edge advancements. Partnering with these organizations allows you to tap into their expertise and develop training programs that directly address the latest industry trends.

- Foster a Culture of Continuous Learning: Encourage a growth mindset within your organization by promoting knowledge sharing and peer-to-peer learning initiatives. This fosters an environment where employees are comfortable exploring new technologies and continuously expanding their skill sets.

Best Practices for Technical Training Programs

Building effective technical training programs requires a strategic approach that considers both content and delivery methods. Here are some key best practices to ensure your training initiatives are engaging, impactful, and drive real results across various industrial settings:

- Tailor Training Programs to Specific Audiences: Develop targeted learning pathways with increasing complexity to ensure content is relevant and engaging for all skill levels. For example, for experienced technicians in a power plant, training might focus on advanced troubleshooting techniques for specific turbine models. New hires, on the other hand, might benefit from foundational training on power plant operations and safety protocols.

- Blended Learning Approach: Combine instructor-led training with online learning modules to leverage the strengths of each format. For instance, an online module could introduce basic safety protocols and hazard identification procedures for construction workers. This can be followed by instructor-led sessions with practical demonstrations and scenario-based exercises to solidify learning and prepare workers for real-world situations.

- Move Beyond Passive Lectures and Traditional Presentations: Incorporate active learning strategies that promote engagement and knowledge retention. This could involve case studies, simulations, group discussions, role-playing exercises, or hands-on activities with real equipment. Simulations can be a powerful tool for training healthcare professionals. Nurses, for example, can participate in simulated patient care scenarios to practice critical decision-making skills and hone their communication and collaboration abilities in a safe, controlled environment.

- Measurement and Evaluation: Build mechanisms to measure the effectiveness of your training programs. Utilize pre- and post-training assessments to gauge knowledge acquisition and skill development. Gather feedback from participants to identify areas for improvement and ensure the training is meeting its objectives.

- Continuous Improvement: Training programs should be a living document, not a static one. Regularly review your curriculum and delivery methods to reflect industry best practices, technological advancements, and feedback from participants.

Leadership’s Role in Promoting Continuous Learning

Creating a culture that prioritizes continuous technical training hinges on strong leadership commitment. Leaders who actively advocate for ongoing professional development send a powerful message that learning and growth are valued within the organization. Here are some key initiatives leaders can implement to foster a thriving learning environment:

- Set the Standard: When leaders take part in training programs and show their dedication to ongoing learning, they really set the right example for everyone else. This not only motivates employees but also provides a strong example for the entire organization.

- Allocate Resources: Effective training requires dedicated resources. Leaders must allocate sufficient budget and personnel to develop and deliver high-quality training programs. This demonstrates a concrete commitment to upskilling the workforce.

- Provide Recognition and Rewards: Recognize and celebrate the efforts employees put into continuous learning. This might include acknowledging when they complete training programs, offering promotions or greater responsibilities based on their new skills, or creating incentive programs to reward their participation in professional development activities.

- Mentorship and Coaching Programs: Promote a culture of knowledge sharing by setting up mentorship or coaching programs. By pairing experienced employees with new hires or those looking to learn new skills, you create a collaborative learning environment. This also allows senior employees to play a key role in the overall growth of the team.

- Offer Flexible Learning Opportunities: Recognize that employees have diverse learning styles and busy schedules. Leaders can support continuous learning by offering a variety of training formats, including online modules, micro-learning opportunities, and after-hours training sessions. Additionally, providing access to industry conferences or online learning platforms demonstrates a commitment to ongoing skill development.

Integration of Digital Tools in Technical Training

The incorporation of digital tools and software into technical training is revolutionizing the way industries train their workforce. These technologies not only enhance the learning experience but also significantly improve training outcomes by offering interactive, engaging, and flexible learning environments.

Virtual Reality (VR) and Augmented Reality (AR)

VR and AR are at the forefront of transforming technical training. VR immerses trainees in a simulated environment where they can practice complex tasks risk-free. For example, VR can simulate electrical circuit assembly processes, allowing trainees to gain proficiency without the safety risks associated with live training. AR overlays digital information onto the real world, aiding in tasks such as machine repair, where real-time data and step-by-step instructions can be displayed over the actual equipment.

Simulation Software

Simulation tools are essential for technical training as they provide a hands-on learning experience without the physical constraints. These tools enable learners to understand complex machinery and systems through detailed simulations that mimic real-world operations. For instance, simulation software can help operators learn the intricacies of operating a chemical plant, including response strategies for potential emergencies, without the risk of actual harm.

Robotics and Automation Training

As robotics and automation become prevalent in industries like manufacturing and logistics, training programs must integrate these technologies into their curriculum. Practical training in robotics programming, operation, and maintenance can prepare workers to manage and troubleshoot automated systems effectively, ensuring smoother transitions and continuous productivity in their roles.

Industrial Internet of Things (IIoT)

IIoT platforms integrate sensors, machines, and analytics to train workers on complex industrial systems through real-time data monitoring and management. This technology helps trainees understand machine behavior under various scenarios, improving predictive maintenance skills and system optimization.

3D Modeling and CAD Software

Training involving 3D modeling and computer-aided design (CAD) software is vital in sectors like manufacturing and construction. These tools help trainees visualize and manipulate machinery components or entire assembly lines in a virtual space, fostering a deeper understanding of equipment design and function.

Digital Twin Technology

Digital twin technology creates a dynamic digital representation of physical systems to simulate real-world conditions and predict outcomes in real-time. This tool is invaluable in industries such as aerospace, automotive, and heavy machinery, where it can be used to model production processes before actual physical execution, thereby optimizing the configurations and improving product quality and system performance.

Wearable Technology

In heavy industries, wearable technology such as smart helmets and augmented reality glasses can facilitate on-the-job training by providing workers with real-time information, procedural steps, and safety alerts. These devices enhance hands-on training, enable remote expert assistance, and ensure that workers are immediately up-to-date with the latest operational protocols.

AI-driven Analytics for Training Customization

Leveraging AI to analyze training outcomes and adapt learning modules to better fit the needs of individual learners or specific job roles can greatly enhance the effectiveness of technical training programs. AI algorithms can help identify skill gaps and recommend personalized learning paths, making training more relevant and targeted.

Final Words

In the dynamic landscape of industrial sectors, the key to sustainable success lies in a skilled and adaptable workforce. By prioritizing continuous technical training, organizations empower their employees to not only keep pace with rapid technological advancements but also become active participants in driving innovation.

This article has explored the multifaceted benefits of ongoing learning programs, from fostering a culture of continuous improvement to optimizing operational efficiency. We have examined methods to address common challenges in implementation and stressed the necessity of continuously updating training programs to align with the dynamic demands of the industrial sector.

The integration of digital tools and leadership’s commitment to fostering a culture of learning are crucial elements in creating a truly effective training ecosystem. Remember, investing in your workforce’s technical development is an investment in the future of your organization. By embracing continuous learning, you can equip your team with the skills and knowledge needed to navigate the technological frontier and lead the charge toward a dynamic and innovative future.